Pinnacle Plastic Products

Pinnacle Plastic Products can work from a sketch, a blueprint, or CAD files to assist you in engineering your part to take advantage of the blow molding process for the best results. Our finishing capabilities include urethane foaming operations for insulating, sound-deadening and increased structural integrity. Drilling, routing, punching, riveting, and insert molding can be provided. We source components, add decals and instruction sheets, assemble, and package your products. Our expert work force is on the job around the clock molding, finishing, assembling and packing a variety of products for customers in many diverse industries.

Call us at

(419) 352-8688

Quick Quote

We have more than 25 years of experience

Services

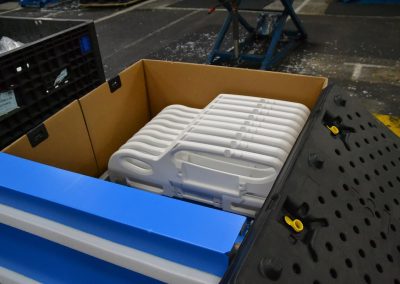

Custom Blow Molding

Our blow molding facility consists of nine presses ranging from 10-50 pounds utilizing 17 accumulator heads blow molding machines…

Full Product Assembly

As a full service blow molder, we provide a broad range of product assembly services to our clients. We can source components, add decals and instructions sheets…

Engineering Assistance

To help you in the production of blow molded plastic products, we offer engineering assistance to help take advantage of the blow molding process…

Secondary Operations

We offer a broad range of secondary operations such as urethane foam filling, drilling, routing, punching, riveting, as well as assembly and full product pack out…

Your Expert Source for blow Molded Solutions and products

Industries Served

Automotive Interior & Exterior

Child Restraint Seating

Construction

Sporting Goods

House wares

Industrial Equipment

Juvenile Furniture

Lawn & Garden

Medical/Pharmaceutical/Health Care Products

Packaging

Point of Purchase Displays

Premiums & Special Markets

Pressure Vessel

Recreational/Outdoor Equipment

Request a Quote for Custom Blow Molding

Gallery

Call us at

(419) 352-8688

Quick

Request a Quote